From TIG to racing: the Nevi titanium bikes

Company Name

Industry

Location

Base material(s)

Solution

Nevi, a leading manufacturer of titanium frame bicycles, has chosen the ADAPTIG TIG torch to tackle the challenges of welding complex geometries with precision and ease.

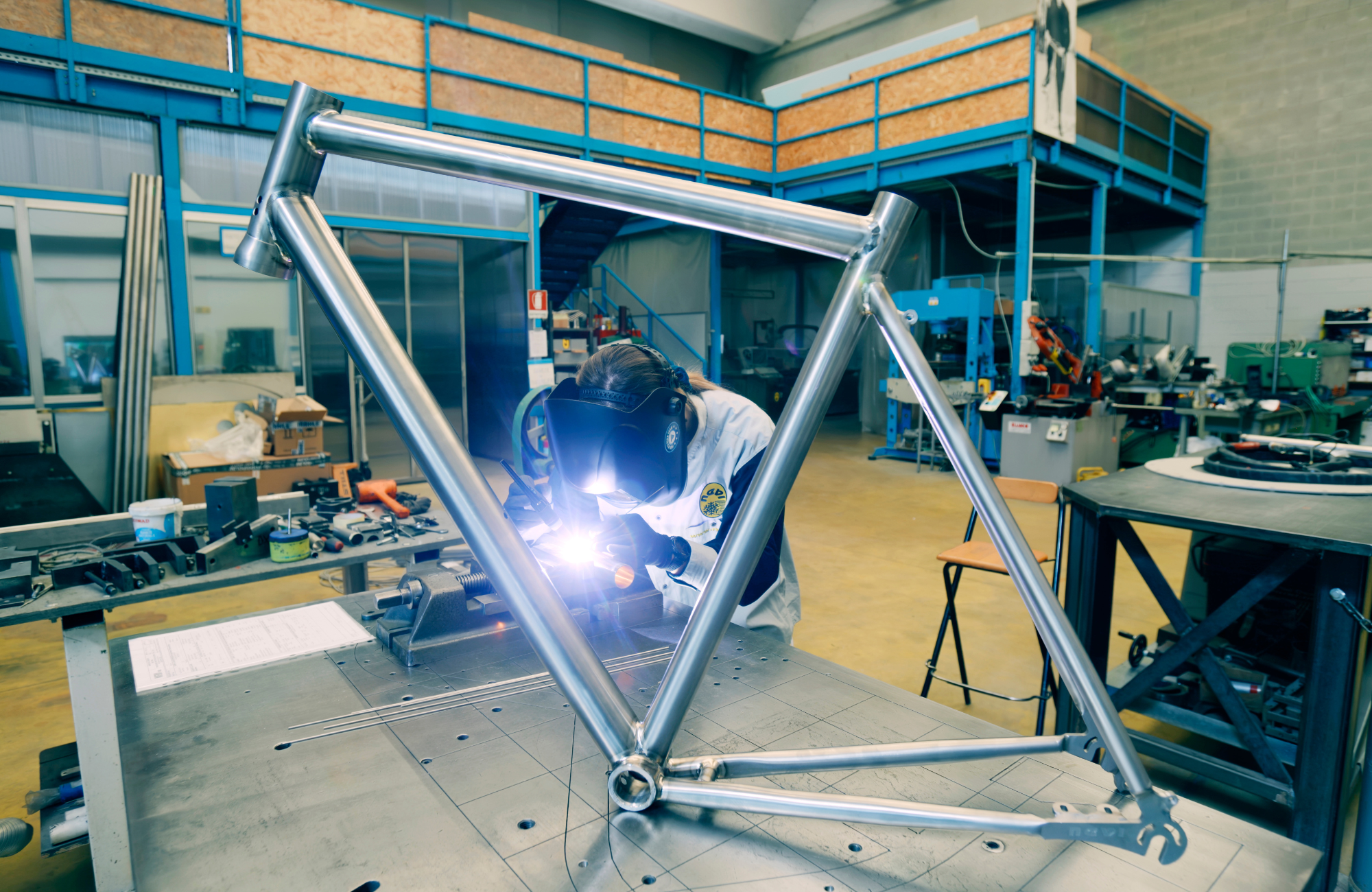

Founded in 1992 in the Bergamo area, Nevi is an international benchmark for the handcrafted production of titanium frames. The company was born out of founder Sergio Finazzi's passion for cycling and is now one of Europe's leading specialists in titanium welding.

Nevi's products are known worldwide by enthusiasts who come to the company directly to purchase their custom-made frames. The bicycles are handcrafted but follow a high-tech welding process. Behind each frame, there is study and continuous dedication, representing a combination of craftsmanship, technology and Made in Italy, appreciated by enthusiasts all over the world.

The welding of titanium, performed with the correct procedures, makes it possible to obtain welded joints with mechanical characteristics similar to or superior to non-welded metal, creating unique bicycles.

Nevi is an ISO 9001:2015 certified company and its welders are 9606-5 and WPQR (angle welding and full penetration butt welding) certified.

Tackling the complexity of titanium welding with maximum precision

Welding titanium is not a simple task: it requires high technical skills and specialised equipment, as it is crucial to avoid any contamination with air that would compromise the mechanical characteristics of the joint.

It is important to avoid contamination with air, because oxygen and nitrogen increase the fragility already at 400 °C.

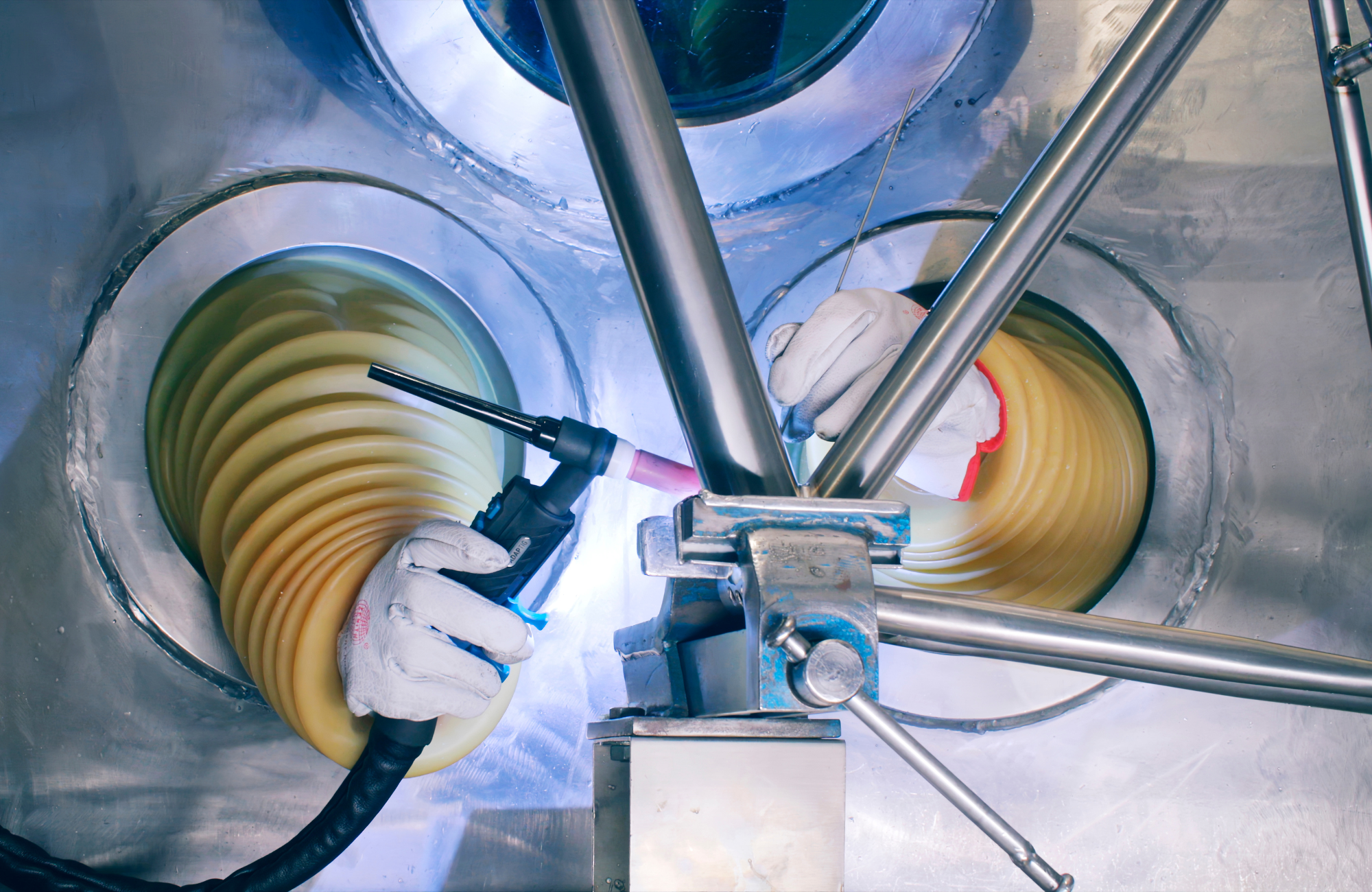

Nevi uses a steel inert gas welding chamber that achieves high vacuum levels before filling with inert gas. The presence of oxygen during the welding process is 0.01%, which is approximately zero.

Nevi's products are processed exclusively by TIG welding to guarantee the highest quality standards.

The main problem? A high-performance torch is needed, capable of operating even inside the inert gas chamber and accurately handling welds on fittings with very narrow and complex angles.

"The new ADAPTIG torch is lighter, easier to handle and allows me to weld even the most complex geometries with greater precision and comfort.

The finger supports are helpful since they make it easier to hold the torch without constant position corrections."

[Andrea Finazzi, specialised titanium TIG welder, Nevi Srl]

The ADAPTIG torch represented a breakthrough for Nevi in handling complex titanium welds. Lightness, cable flexibility and improved ergonomics were the decisive factors that convinced the company to equip itself with this new tool.

The new ADAPTIG torch - recommended by our specialised partner Sigma International - allows Nevi to more easily perform welds on complicated geometries such as pipe connections with very low angles.

Thanks to its compact and balanced design, ADAPTIG allows easy manoeuvring even inside the inert gas chamber, where every movement is constrained by gloves and insulated sleeves. The flexible cable allows natural rotation around the tubes, which is essential to achieving uniform welds on narrow fittings.

The adjustable finger supports allow the grip to be customised to the working position, increasing comfort and reducing fatigue during extended TIG welding sessions. For Nevi's welders, they are helpful when holding the torch against the palm and can be adjusted for a more comfortable grip, depending on how close the workpiece is to be welded. This facilitates torch support and limits position corrections.

Direct experience in the field has shown that ADAPTIG is a tailor-made solution for those who, like Nevi, cannot compromise when it comes to precision and quality.

The result? Aesthetically flawless and mechanically reliable welded joints, ready to become the basis of unique frames appreciated worldwide.